Brass Threaded Forged Fitting Supplier

Dimension and wall thickness

Pipe diameters

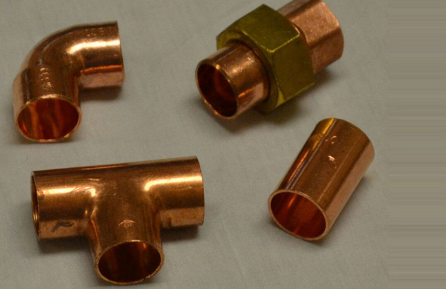

Brass Forged Fitting, Bass Carpenter Threaded Tee, Brass Threaded BEND, Brass Threaded Cross, Buy Brass Socket Weld Fittings, Brass Screwed Fittings Exporter, Brass UNS C36000 Threaded Coupling Stockist, Brass Threaded Forged Fittings, ASTM B62 Brass Threaded Elbow, Brass Threaded Cap Manufacturer and Suppliers In Mumbai, India.

Brass Threaded Equal Tee, Brass Threaded Pipe Elbow, Brass Threaded Bushing, Brass Hexagonal Plug, Brass Threaded Forged 90deg. Elbow, Brass Hex Plug, Carpenter Threaded Exporter, Brass Threaded Plug, ASME 16.15 Brass Threaded Fittings, Brass Lateral Tee, ASME SB62 Brass Threaded Forged Fittings Supplier, Brass Forged Fittings Manufacturer in India.

Detailed Information

Manufacturer & Supplier of Brass Threaded Forged Fitting in Mumbai, India

Brass, an alloy (primarily) of copper and zinc, is one of the most common forging materials used for making fittings. Obviously, there are likewise different metals that can be utilized to forge fittings, like treated steel or aluminum. The Brass Forged Fittings have up to 63% copper and 35% zinc with iron and lead in the composition. Our Brass Threaded Forged Fittings consist of 18 % minimum chromium content provides excellent corrosion and oxidation resistance. These Brass Threaded Forged Elbow Fittings must contain at least 10.5 percent chromium, which has the innate ability to form a passive layer that prevents corrosion. These Brass Threaded Forged Tee Fittings may contain much higher chromium levels, and additional alloying ingredients like molybdenum, nickel, aluminum, copper, titanium, nitrogen, selenium, and phosphorous. Newzel Industry is a well-known Manufacturer & Supplier of Brass Threaded Forged Fittings in Mumbai, India.

Brass fittings are in high demand because of some inherent properties which make them superior to other materials. Brass fittings are mainly used for water, gases, chemicals, fire sprinkler systems, etc. Brass fittings made by forging and machining are available in a wide variety of shapes and thread sizes to connect, control any air or liquid flow in a pipe or tube. These Brass Threaded Forged Coupling Fittings contain between 16 percent and 24 percent chromium and up to 35 percent nickel — as well as small amounts of carbon and manganese. The slightly higher price point of these Brass Threaded Forged Bend Fittings is well worth it in areas with high chloride exposure, especially the coast and heavily salted roadways.

Cities We Delivered

New York City, Los Angeles, Chicago, Houston, Phoenix, Philadelphia, San Antonio, San Diego, Dallas, San Jose, Austin, Jacksonville, Fort Worth, Columbus, Charlotte, San Francisco, Indianapolis, Seattle, Denver, Washington, Boston, El Paso, Nashville, Detroit, Oklahoma City, Portland, Las Vegas, Memphis, Louisville, Baltimore, Milwaukee, Albuquerque, Tucson, Fresno, Mesa, Sacramento, Atlanta, Kansas City, Colorado Springs, Omaha, Raleigh, Miami, Long Beach, Virginia Beach, Oakland, Minneapolis, Tulsa, Tampa, Arlington, New Orleans, Wichita, Bakersfield, Cleveland, Aurora, Anaheim, Honolulu, Santa Ana, Riverside, Corpus Christi, Lexington, Henderson, Stockton, Saint Paul, Cincinnati, St. Louis, Pittsburgh, Greensboro, Lincoln, Anchorage, Plano, Orlando, Irvine, Newark, Durham, Chula Vista, Toledo, Fort Wayne, St. Petersburg, Laredo, Jersey City, Chandler, Madison, Lubbock, Scottsdale, Reno, Buffalo, Gilbert, Glendale, North Las Vegas, Winston-Salem, Chesapeake, Norfolk, Fremont, Garland, Irving, Hialeah, Richmond, Boise, Spokane, Baton Rouge, Tacoma, San Bernardino, Modesto, Fontana, Des Moines, Moreno Valley, Santa Clarita, Fayetteville, Birmingham, Oxnard, Rochester, Port St. Lucie, Grand Rapids, Huntsville, Salt Lake City, Frisco, Yonkers, Amarillo, Glendale, Huntington Beach, McKinney, Montgomery, Augusta, Aurora, Akron, Little Rock, Tempe, Columbus, Overland Park, Grand Prairie, Tallahassee, Cape Coral, Mobile, Knoxville, Shreveport, Worcester, Ontario, Vancouver, Sioux Falls, Chattanooga, Brownsville, Fort Lauderdale, Providence, Newport News, Rancho Cucamonga, Santa Rosa, Peoria, Oceanside, Elk Grove, Salem, Pembroke Pines, Eugene, Garden Grove, Cary, Fort Collins, Corona, Springfield, Jackson, Alexandria, Hayward, Clarksville, Lakewood, Lancaster, Salinas, Palmdale, Hollywood, Springfield, Macon, Kansas City, Sunnyvale, Pomona, Killeen, Escondido, Pasadena, Naperville, Bellevue, Joliet, Murfreesboro, Midland, Rockford, Paterson, Savannah, Bridgeport, Torrance, McAllen, Syracuse, Surprise, Denton, Roseville, Thornton, Miramar, Pasadena, Mesquite, Olathe, Dayton, Carrollton, Waco, Orange, Fullerton, Charleston, West Valley City, Visalia, Hampton, Gainesville, Warren, Coral Springs, Cedar Rapids, Round Rock, Sterling Heights, Kent, Columbia, Santa Clara, New Haven, Stamford, Concord, Elizabeth, Athens, Thousand Oaks, Lafayette, Simi Valley, Topeka, Norman, Fargo, Wilmington, Abilene, Odessa, Columbia, Pearland, Victorville, Hartford, Vallejo, Allentown, Berkeley, Richardson, Arvada, Ann Arbor, Rochester, Cambridge, Sugar Land, Lansing, Evansville, College Station, Fairfield, Clearwater, Beaumont, Independence, Provo, West Jordan, Murrieta, Palm Bay, El Monte, Carlsbad, North Charleston, Temecula, Clovis, Springfield, Meridian, Westminster, Costa Mesa, High Point, Manchester, Pueblo, Lakeland, Pompano Beach, West Palm Beach, Antioch, Everett, Downey, Lowell, Centennial, Elgin, Richmond, Peoria, Broken Arrow, Miami Gardens, Billings, Jurupa Valley, Sandy Springs, Gresham, Lewisville, Hillsboro, Ventura, Greeley, Inglewood, Waterbury, League City, Santa Maria, Tyler, Davie, Lakewood, Daly City, Boulder, Allen, West Covina, Sparks, Wichita Falls, Green Bay, San Mateo, Norwalk, Rialto, Las Cruces, Chico, El Cajon, Burbank, South Bend, Renton, Vista, Davenport, Edinburg, Tuscaloosa, Carmel, Spokane Valley, San Angelo, Vacaville, Clinton, Bend, Woodbridge.

Brass Threaded Fittings Material Specification Chart

| Specifications | ASTM B62 & ASME B62 |

| Size Range | Seamless Butt-Weld Fitting: From 1/2″ – 10″

Welded Buttweld Fitting: From 1/2″ – 48″ |

| Dimension | ASME/ ANSI B16.9 | ASME B16.28 | MSS-SP-43 | BS1560 | BS4504 | BS10 |

| Bending Radius | Radius=1 D, 2D, 3 D, 5D, 6D, 8 D, 10D |

| Thickness of Fitting | SCH10, SCH 20, SCH30, STD SCH40, SCH80, SCH60, XS, SCH100, SCH 120, SCH140, SCH 160, XXS available with NACE MR 01-75 |

| Size Ranges | ½” NB to 24″ NB in Schedule 10s, 40s, 80s, 160s, XXS. |

| Process of Manufacturing | Push, Press, Cast, Forge. |

| Types | Welded | Seamless | Fabricated |

Brass Tube to Male Pipes Fitting Chemical Composition

| Brass | Cu | Fe | Pb | Zn |

| Min./Max. | 60.0-63.0 | 0.35 | 2.5-3.0 | Rem. |

| Nominal | 61.5 | – | 2.7 | 35.4 |

Brass Tube to Male Pipes Fitting Physical Properties

|

Properties |

US Customary |

|

Melting Point -Liquidus |

1650 F |

|

Melting Point -Solidus |

1630 F |

|

Density |

0.307 lb/in3at 68 F |

|

Electrical Resistivity |

39.90 ohms – cmil/ft @ 68 F |

|

Electrical Conductivity |

26 %IACS @ 68 F |

|

Thermal Conductivity |

67 Btu · ft/(hr · ft2·oF)at 68F |

|

Modulus of Elasticity in Tension |

14000 ksi |

Pressure Ratings of Brass Compression Fittings

| NPS

(inch) |

OD

(inch) |

Pipe Sch. | Wall

Thk. (in) |

Temperature (oF) | |||||

| 100 | 200 | 300 | 400 | 500 | 600 | ||||

| Allowable Stress (Pressure Rating) | |||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | ||||

| 1″ | 1.315 | 40 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 |

| 1.315 | 80 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | |

| 1.315 | 160 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | |

| 1 1/2″ | 1.900 | 40 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 |

| 1.900 | 80 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | |

| 1.900 | 160 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | |

| 2″ | 2.375 | 40 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 |

| 2.375 | 80 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | |

| 2.375 | 160 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | |

| 3″ | 3.500 | 40 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 |

| 3.500 | 80 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | |

| 3.500 | 160 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | |

| 4″ | 4.500 | 40 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 |

| 4.500 | 80 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | |

| 4.500 | 160 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | |

| 5″ | 5.563 | 40 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 |

| 5.563 | 80 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | |

| 5.563 | 160 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | |

| 6″ | 6.625 | 40 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 |

| 6.625 | 80 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | |

| 6.625 | 160 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | |

| 8″ | 8.625 | 40 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 |

| 8.625 | 80 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | |

| 8.625 | 160 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | |

| 10″ | 10.750 | 40 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 |

| 10.750 | 80 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | |

| 10.750 | 160 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | |

Our Products

Related Products

Before You Go…

would you like a copy of our Handy Guide to leasing an industrial unit straight to your inbox?

Call Us At

Feel free to call on

+91 79774 55576

022-66394744/45

Drop Mail

For Domestic Queries:

jay@newzelindustries.com

For International Queries:

info@newzelindustries.com